Reflective optics, which rely on mirrors to direct and manipulate light, play a crucial role in a wide range of fields, including astronomy, life sciences, and industrial applications. These systems offer several advantages over refractive optics, particularly in high-precision environments where laser focusing and multispectral imaging are essential.

At the core of reflective optics are mirrors, which are designed to reflect light. When light hits a mirror, it follows the law of reflection, meaning the angle at which the light strikes the surface is the same as the angle at which it reflects. Mirrors come in various shapes and sizes, and their effectiveness depends largely on the quality of the reflective surface and the type of coating applied.

There are two primary types of mirrors used in reflective optics, categorized by where the reflective coating is placed:

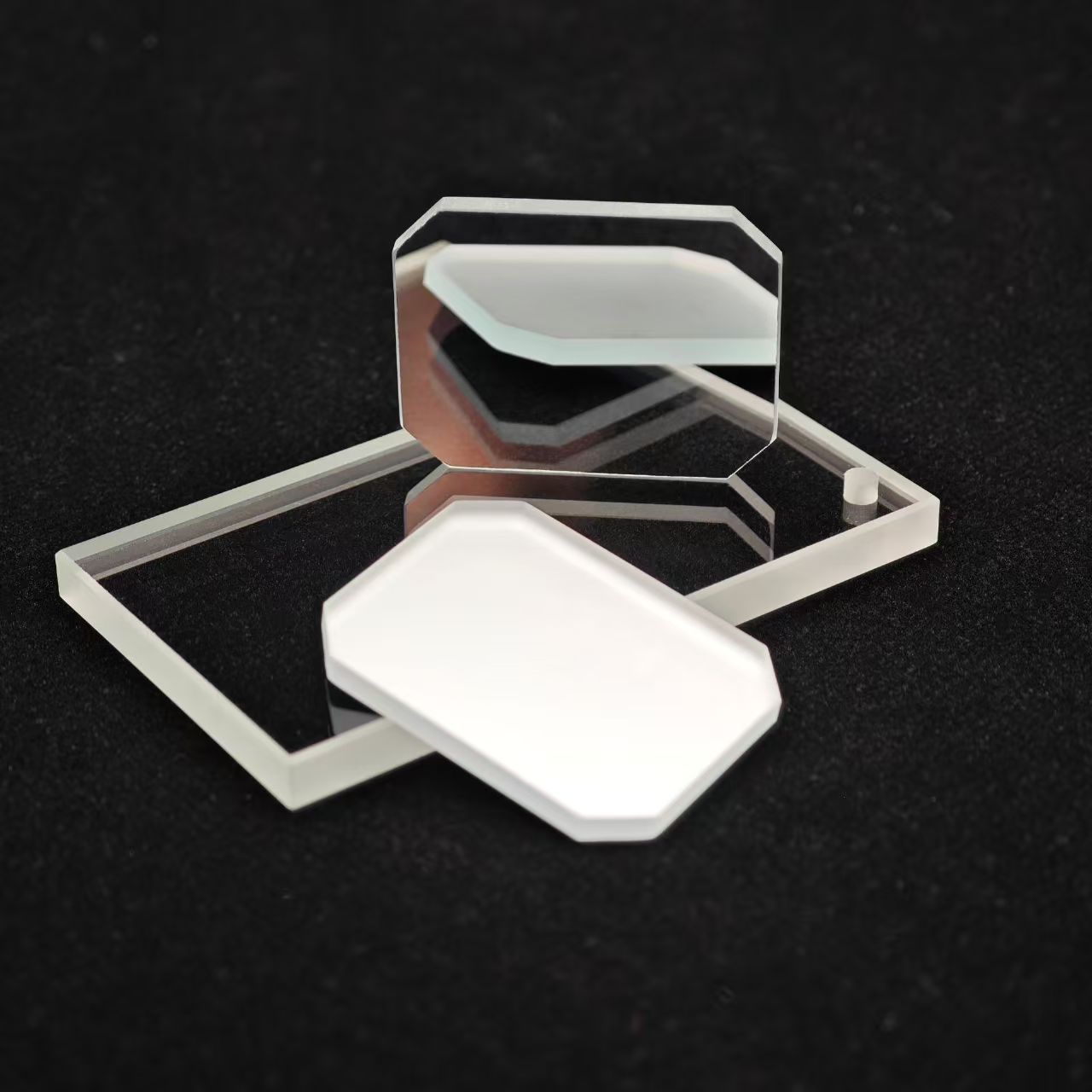

First Surface Mirrors: In these mirrors, the coating is applied to the front surface, ensuring that light reflects off the coating before reaching the substrate. This design eliminates distortion, making it ideal for precision optical applications.

Second Surface Mirrors: These mirrors have the reflective coating on the back of the glass or substrate. Light passes through the transparent substrate before being reflected, which helps protect the coating but may cause some image distortion, making it less suitable for high-precision tasks.

Types of Coatings in Reflective Optics

The choice of coating is critical for both the durability and performance of a mirror. Different coating methods, such as physical vapor deposition, chemical vapor deposition, and sputter deposition, are used to create highly reflective, smooth surfaces. The most common coatings include:

Metal Coatings: Gold, silver, and aluminum are frequently used for their high reflectivity. However, these metals are prone to damage and often require protective dielectric overcoats to enhance their durability.

Dielectric Coatings: These coatings consist of multiple thin layers of material with alternating refractive indices. Though the individual materials aren’t highly reflective, the layers work together to reflect specific wavelengths of light efficiently. Dielectric coatings are more resistant to laser damage but are typically limited to narrow spectral ranges, usually in the visible and near-infrared (NIR) regions.

We’d be more than happy to discuss your projects and how to best bring them to fruition. sales@hr-optics.com

售前客服

售前客服